Introduction

ASTM A588 Grade B is a high-strength, low-alloy structural steel known for its exceptional atmospheric corrosion resistance. Commonly referred to as weathering steel, ASTM A588 Grade B is widely used in various infrastructure projects, including bridges, buildings, railway vehicles, shipping containers, and outdoor sculptures. The steel’s unique alloying elements form a protective rust-like patina that inhibits further corrosion, significantly extending the material’s lifespan without requiring painting or frequent maintenance.

For buyers worldwide, sourcing high-quality ASTM A588 Grade B material that meets stringent technical standards is crucial to ensure long-term durability and structural integrity. This blog outlines 6 essential tips to help buyers verify specifications, understand mechanical properties, confirm sizing and surface quality, evaluate supplier reliability, and navigate pricing factors.

Tip 1: Verify Material Standards

Understanding ASTM A588 Grade B Specifications

Before purchasing, buyers must ensure that the steel fully complies with ASTM A588/A588M Grade B specifications. This includes confirming chemical composition, mechanical properties, and manufacturing process requirements as outlined by ASTM International.

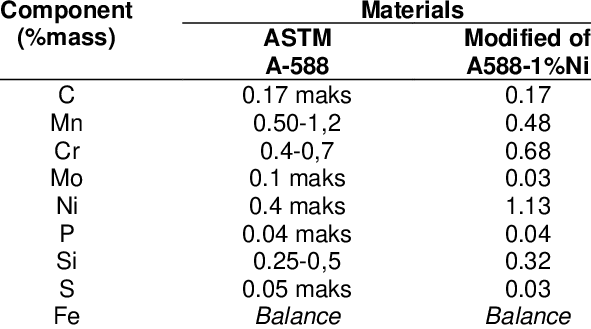

Chemical Composition

The alloying elements in ASTM A588 Grade B play key roles in providing corrosion resistance and strength. The typical chemical composition is as follows:

| Element | Typical Range (%) | Function |

|---|---|---|

| Carbon (C) | ≤ 0.19 | Provides strength and hardness |

| Manganese (Mn) | 0.75–1.35 | Enhances strength and toughness |

| Phosphorus (P) | 0.04–0.15 | Promotes formation of protective patina |

| Sulfur (S) | ≤ 0.05 | Controlled to avoid brittleness |

| Silicon (Si) | 0.15–0.50 | Acts as a deoxidizer, improves strength |

| Copper (Cu) | 0.20–0.40 | Improves corrosion resistance |

| Chromium (Cr) | 0.40–0.65 | Enhances corrosion resistance |

| Nickel (Ni) | ≤ 0.50 | Improves toughness and corrosion resistance |

Key Insight: Copper, chromium, and nickel are the cornerstone elements that enable ASTM A588 Grade B steel to develop a dense, adherent patina, protecting it against atmospheric corrosion.

Equivalent International Standards

For global buyers, it’s important to recognize equivalent standards to ASTM A588:

- EN 10025-5 S355J2W (European weathering steel)

- GB/T 4171 Q355NH (Chinese weathering steel standard)

Understanding these equivalences helps buyers source from multiple regions while ensuring compatibility with project specifications.

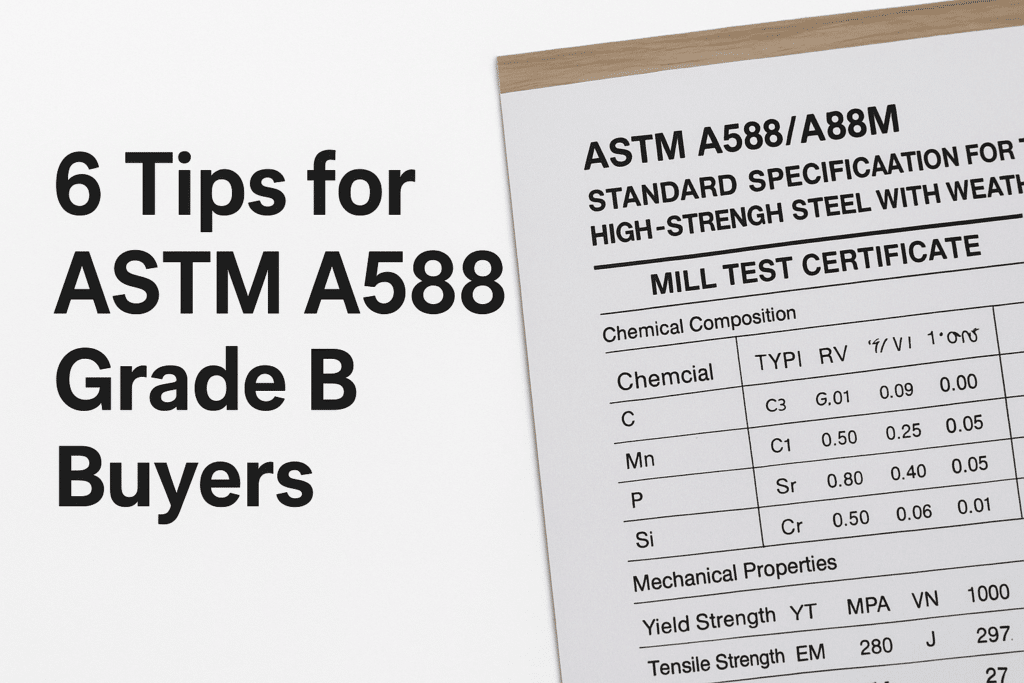

Mill Test Certificate (MTC)

Demand an official MTC from your supplier confirming that the steel meets all ASTM requirements for chemical composition and mechanical properties. The MTC must be traceable to the production batch and include heat number, chemical analysis, tensile test results, and impact testing data.

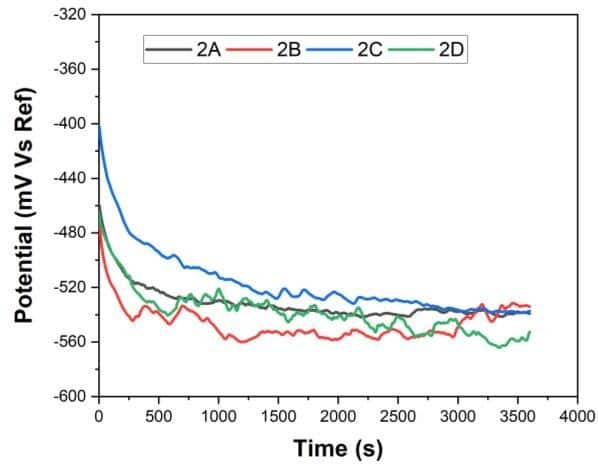

Tip 2: Check Mechanical Properties

Mechanical Properties Overview

Mechanical properties determine the steel’s load-bearing capacity, toughness, and ability to withstand harsh environmental conditions. Below is the typical range for ASTM A588 Grade B:

| Property | Unit | Minimum Value |

|---|---|---|

| Yield Strength (YS) | MPa | 345 |

| Tensile Strength (TS) | MPa | 485 – 620 |

| Elongation (El) | % | ≥18 |

| Charpy V-Notch Impact Energy (-20°C) | J | ≥27 |

Importance of Each Property

- Yield Strength: The minimum stress the steel can withstand without permanent deformation. Critical for structural safety margins.

- Tensile Strength: Maximum stress before fracture; indicates toughness.

- Elongation: Measures ductility; higher values imply better formability.

- Impact Energy: Reflects resistance to brittle fracture, especially in cold environments.

Testing Standards

Ensure your supplier’s test methods comply with ASTM A370 for mechanical testing and ASTM E23 for impact testing. Require recent batch-specific test reports, not generic data sheets.

Practical Buying Advice

For critical infrastructure projects in cold or coastal environments, request full mechanical testing for each batch delivered. Inquire about the supplier’s quality control processes and certifications related to mechanical property testing.

Tip 3: Confirm Size and Tolerance

Typical Dimensions and Delivery Conditions

ASTM A588 Grade B plates are commonly available in these ranges:

- Thickness: 6 mm to 50 mm (standard thicknesses preferred by most buyers: 8, 10, 12, 16, 20, 25 mm)

- Width: 1500 mm to 3000 mm

- Length: 6000 mm to 12000 mm (custom lengths may be available)

Delivery conditions include:

- Hot Rolled (HR): Standard finish with mill scale, suitable for most structural applications.

- Normalized (N): Heat-treated to improve toughness and reduce residual stresses.

- Controlled Rolled (CR): Mechanically processed for refined grain size and enhanced strength.

ASTM A6/A6M Tolerances

Ensure the supplier’s dimensions conform to ASTM A6/A6M tolerances for plate products:

| Dimension | Thickness Tolerance | Width Tolerance | Length Tolerance |

|---|---|---|---|

| Thickness ≤ 6 mm | ±0.4 mm | ±6.4 mm | ±12.7 mm |

| Thickness > 6 mm | ±0.5 mm | ±6.4 mm | ±12.7 mm |

Why Tolerances Matter

Inaccurate plate sizes can cause significant delays and increased costs during fabrication and welding. For example, if plates are oversized or undersized beyond tolerance, they may not fit precise connections or may require additional machining.

Case Study

A recent bridge project faced welding rework after receiving ASTM A588 plates with thickness exceeding tolerance by 0.8 mm, which led to misalignment and structural integrity concerns. This highlights why size verification before shipment is essential.

Tip 4: Inspect Surface Quality

Surface Condition and Its Impact

Surface quality affects the development of the protective rust patina and long-term corrosion resistance. Common surface issues include:

- Cracks or laminations: Can propagate corrosion internally, weakening the structure.

- Scale or rust deposits: Excessive mill scale or irregular rust can cause uneven patina formation.

- Inclusions or slag: Non-metallic inclusions can create corrosion initiation sites.

Typical Surface Finishes

- Mill Finish: Standard hot-rolled finish with mill scale intact; suitable for many structural uses.

- Shot Blasted: Removes mill scale and surface contaminants, promoting uniform patina development.

- Pickled: Acid cleaned to remove scale; less common for weathering steel since some mill scale is beneficial.

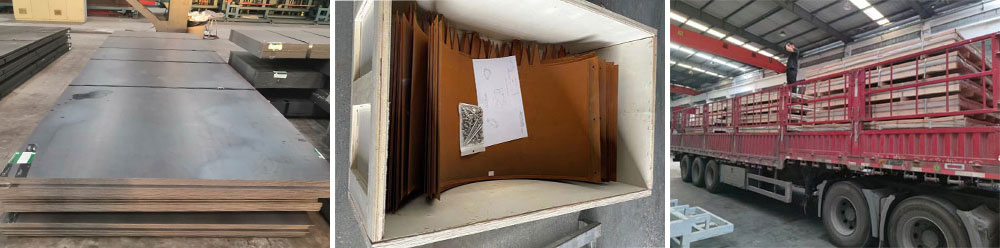

Packaging and Protection for Export

For international shipments, proper packaging prevents damage:

- Anti-rust oil coating: A Thin film of protective oil is applied to plate surfaces.

- Waterproof wrapping: Polyethylene film or tarpaulin covering.

- Strapping and blocking: Secure plates with steel bands and wood blocking inside containers to avoid shifting.

Advice for Buyers

Request surface photos from suppliers before shipment. Insist on appropriate protective measures for overseas transport, especially to humid or coastal destinations.

Tip 5: Evaluate Supplier Reliability

Certifications and Experience

Choose suppliers with proven credentials:

- ISO 9001: Quality management system certification ensures consistent product quality.

- CE Marking: For compliance with European regulations.

- AISC Certification: Indicates steel fabricators meet American Institute of Steel Construction standards.

Track Record with Export Projects

Ask for references or case studies demonstrating previous exports of ASTM A588 Grade B to your region or similar applications. Experienced suppliers understand export logistics and quality control.

Supply Chain Stability

Consider suppliers backed by large steel mills or integrated supply chains to guarantee continuous availability, especially for large or repeat orders.

Technical Support and After-Sales Service

Reliable suppliers offer technical consultations, including welding guidelines, corrosion resistance testing advice, and on-site support if needed.

Risk Example

Inexperienced suppliers lacking export experience may cause shipment delays, inconsistent quality, or incomplete documentation, putting your project timeline and budget at risk.

Tip 6: Understand Pricing Factors

Raw Material and Production Costs

Steel prices fluctuate with global iron ore and scrap prices, energy costs, and mill capacity. ASTM A588 Grade B’s alloying elements (Cu, Cr, Ni) add a premium compared to standard carbon steel.

Order Volume and Lead Time

Large volume orders often qualify for bulk discounts and prioritized production schedules. Longer lead times might reduce prices but increase inventory holding costs.

Transportation and Customs Duties

International freight rates vary by route and season. Choose efficient shipping methods and verify applicable tariffs, taxes, and import regulations in your country.

Market Volatility and Contracting

Due to volatile steel markets, consider price-lock contracts or staged deliveries to mitigate risk. Monitor steel indices like SteelBenchmarker and MetalMiner for market trends.

Negotiation Tips

- Consolidate orders to reduce per-unit shipping cost.

- Confirm clear payment and delivery terms upfront.

- Include quality assurance clauses to protect against substandard material.

Conclusion

Purchasing ASTM A588 Grade B weathering steel requires a comprehensive understanding of material standards, mechanical properties, sizing tolerances, surface quality, supplier reliability, and pricing dynamics. By following these 6 tips, international buyers can confidently source steel that ensures long-term corrosion resistance, structural safety, and cost-effective performance for critical infrastructure projects.

When procuring ASTM A588 Grade B steel, insist on traceable Mill Test Certificates, detailed mechanical testing, and transparent communication with reputable suppliers. This approach minimizes risks, avoids costly delays, and guarantees your projects achieve the durability and quality they demand.

12 Responses

Wonderful web site Lots of useful info here Im sending it to a few friends ans additionally sharing in delicious And obviously thanks to your effort

Its like you read my mind You appear to know a lot about this like you wrote the book in it or something I think that you could do with some pics to drive the message home a little bit but instead of that this is fantastic blog An excellent read I will certainly be back

Hello my loved one I want to say that this post is amazing great written and include almost all significant infos I would like to look extra posts like this

Just wish to say your article is as surprising The clearness in your post is just cool and i could assume youre an expert on this subject Fine with your permission allow me to grab your RSS feed to keep updated with forthcoming post Thanks a million and please keep up the enjoyable work

Simply desire to say your article is as surprising The clearness in your post is simply excellent and i could assume you are an expert on this subject Fine with your permission let me to grab your feed to keep up to date with forthcoming post Thanks a million and please carry on the gratifying work

Thank you for the auspicious writeup It in fact was a amusement account it Look advanced to far added agreeable from you However how can we communicate

Excellent blog here Also your website loads up very fast What web host are you using Can I get your affiliate link to your host I wish my web site loaded up as quickly as yours lol

Wow amazing blog layout How long have you been blogging for you made blogging look easy The overall look of your web site is magnificent as well as the content

Your blog is a testament to your dedication to your craft. Your commitment to excellence is evident in every aspect of your writing. Thank you for being such a positive influence in the online community.

Your article helped me a lot, is there any more related content? Thanks!

is concise, practical, and highly informative. By focusing on clear, actionable tips, it helps buyers quickly understand key considerations such as material standards, performance requirements, and purchasing precautions. The straightforward structure makes the content easy to digest, while the professional tone builds trust and credibility. Overall, the article gives readers a strong sense of clarity and confidence when sourcing ASTM A588 Grade B steel.

Your point of view caught my eye and was very interesting. Thanks. I have a question for you.